In the mesmerizing world of Luxury Marble & Stones trade, Sarna Stonex is not merely a brand but an emblem of trust, opulence and sophistication, carrying more than 50 years of experience.

The journey began with the vision to provide unparalleled quality of imported as well as Indian marble and granite for the connoisseurs of luxury with the establishment of Sarna & Co. in the year 1978 at Lucknow.

Sarna & Co. kept evolving with the times & the entrance of the younger generation into the business brought about landmark changes which added to the growth of the business. From establishing ‘Harvinder Granite and Marbles’ (1994) as a subsidiary firm to opening ‘Sarna Sons’ (1999), Chinhat, Lucknow, the two brothers, ANJANDEEP SARNA & SANDEEP SARNA brought about a revolutionary shift in the way Lucknow saw & used marbles.

With time, the company grew from having only one warehouse to having three warehouses and expanded into Marble import in the year 2002, eventually transforming into Sarna Stonex in 2008.

Over the years, owing to EXCEPTIONALLY HIGH PRODUCT QUALITY AND SERVICE STANDARDS, Sarna Stonex became a trusted name with government departments such as Uttar Pradesh Rajkiya Nirman Nigam(UPRNN), Department of Social Welfare(DSW), Public Works Department(PWD) as well as mega real estate and construction companies.

The year 2015 became a pivotal year in the story of Sarna Stonex as the company emerged as a trailblazer in the marble and granite trade by securing the prestigious contract for SUPPLYING STONE DURING THE CONSTRUCTION OF THE MOST ICONIC BUILDING IN UTTAR PRADESH – LOK BHAVAN, OFFICE OF THE HON’BLE CHIEF MINISTER OF UTTAR PRADESH.

In the year 2016, the company reached another milestone by becoming THE FIRST RETAILER TO INTRODUCE LARGE SIZE, DESIGNER CERAMIC TILES IN UTTAR PRADESH, changing the way customers looked & bought tiles.

Today, the company focuses on selling MADE IN INDIA TILES at all showrooms highlighting proudly the name of our country.

By developing a fairly large and reliable supply chain by the year 2017, Sarna Stonex became THE ONLY DIRECT IMPORTER OF MARBLE in Uttar Pradesh.

Today, Sarna Stonex proudly supplies the finest Imported Marbles from more than 11 countries to its customers across 150+ cities in India, ensuring high standards of quality control and fair pricing due to zero intermediaries.

In the year 2021, Sarna Stonex established a mega stone processing factory called HI-LINE STONE INDIA PVT. LTD. in KISHANGARH, DIST. AJMER (RAJASTHAN) just 130 Kilometers from Jaipur, the largest marble retail market in Asia.

Coming soon to life, this factory, featuring 2 GANG SAWS and an impressive 45000 SQ.FT. DISPLAY CENTER, will help us in reaching out and fulfilling the requirements of Imported Marbles, Granites and Exotic Stones to all parts of India.

Highlights:

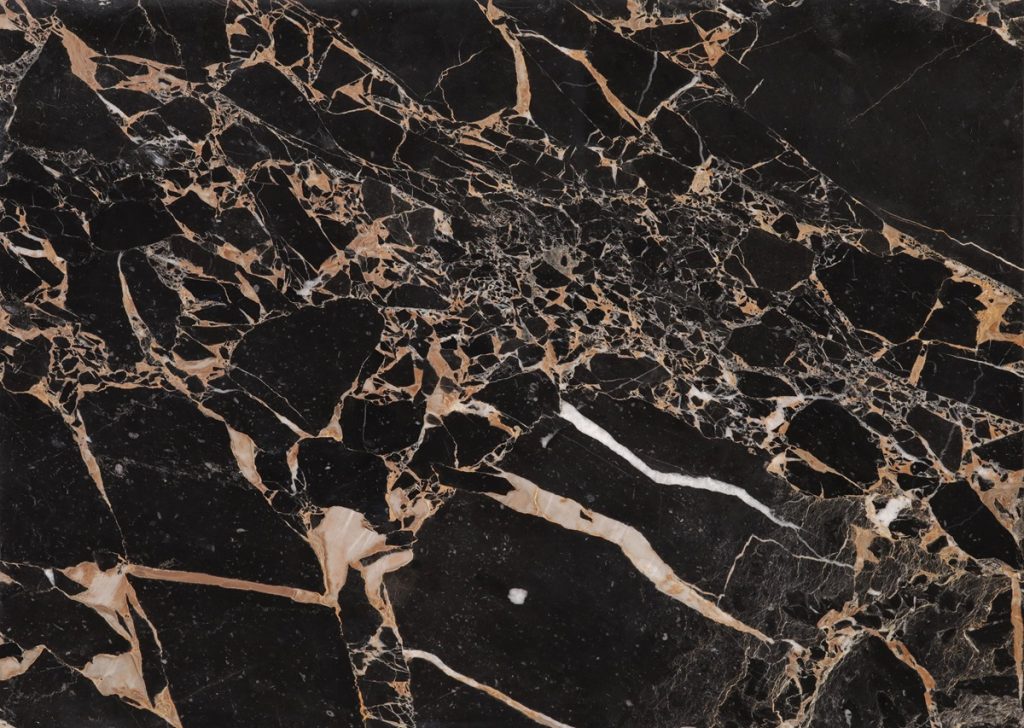

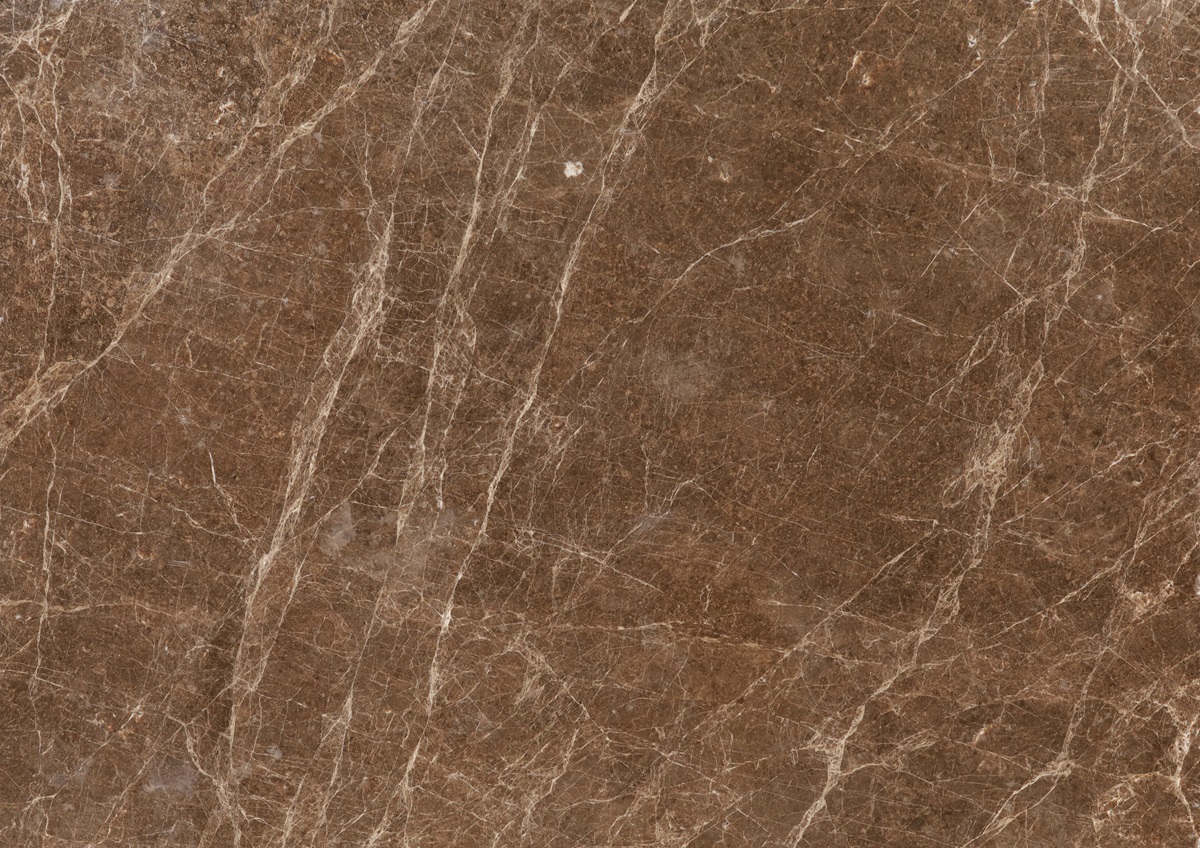

At Sarna Stonex, we ensure that all our Marble is sourced ethically from the best natural Marble reserves across the globe and in India.

The best marble blocks are imported and unloaded in the modern processing facility in Kishangarh, Rajasthan, using a gantry yard.

Once the stone blocks are extracted, state of the art machinery is used to clean and dress the block’s surface of any impurities, natural residues or uneven edges. Following which the blocks are transported via land and sea to our factory.

To smooth the surface and get rid of dust, the block is put through a grinding and blowing process. After applying fiberglass net to each side of the block, sheets are placed on top. The installed pipes are used to allow Tenax specially prepared epoxy to enter the block. In order to increase the block’s durability and guarantee that every crevice is sealed shut, it is subjected to a vacuum process.

The reinforced blocks are cut to an exact inch by the gangsaw machinery in accordance with the standard international dimensions of 18+ mm and 20+ mm thickness.

Thickness: 18+ & 20+ mm We can also make custom dimensions to meet the needs of our clients.

To increase the slab’s strength, Italian epoxy is applied to its front side and stored to allow for penetration. For increased density, Italian epoxy is reapplied to the slab’s front side. Heating chambers are used to heat slabs.

The slab’s visual appeal and shine are improved with Breton Polishing equipment, giving an infinite array of custom finishes and textures, including polished, honed, leather, and many more.

Every stage of the process involves a thorough series of tests and quality checks for every product.

Managing Director

A small river named Duden flows by their place and supplies it with the necessary

Managing Director

Managing Director

A small river named Duden flows by their place and supplies it with the necessary

Managing Director

Managing Director

A small river named Duden flows by their place and supplies it with the necessary

Managing Director

Agree That My Submitters Data Is Being Collected

Craft By Align Solutions